Crematorium Siesegem in Aalst opened

The new "Siesegem" crematorium in Aalst was opened on 6 September 2018. According to the client, the Westlede intermunicipal company, it is one of a kind. "In Europe and maybe even the world", says director Kris Coenegrachts. "The incinerators and the filter installation are visible to the public." On the passage where people can walk freely to and from the meadow, you pass large windows behind the ovens and installation. You can not see it from afar because there is still a wall a few meters away from the glass wall.

The message is that they have nothing to hide. In addition, one wants to make clear that crematoria are not polluting for the air, that only hot air comes from the chimney.

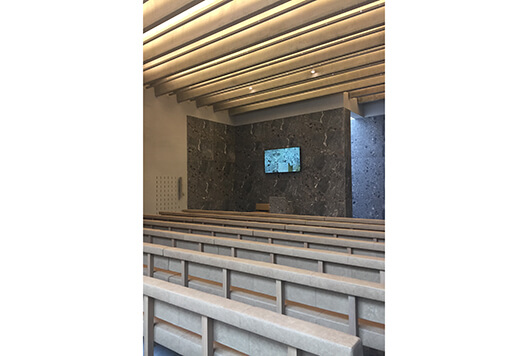

The goal was to design a building that connects with the landscape, so that the tranquility could comfort and empower visitors. The key to achieving this was the linearity, the rhythmic layout of alternating patios, open courtyards, glass walls and - in the chapels - column-free spaces. Thanks to the use of renewable and low-carbon materials and the state-of-the-art heat recovery systems, zero-energy consumption is achieved, which makes sustainability an additional pillar for the design.

Pieters

Pieters was involved in the project from the competition, which was won by Kaan architecten. Pieters has made the structural design in close consultation with Kaan architects, a structure that consists of a frame of concrete columns, beams and concrete walls.

The main supporting structure has been poured into the work. The floors consist of hollow core slabs, wide slabs and double T beams for the large spans of the halls and the entrance awning. The stability is derived from the columns and walls clamped into the foundation. The crematorium requires an installation with large air ducts that are integrated in the foundation. In a BIM, the installation design and the structural design are carefully coordinated. The entire crawl space is full of channels and pipes that, thanks to careful coordination, fit perfectly through the recesses in the foundation beams. Pieters also made the cost estimate and the specifications for the structure, with which the project was put out to tender. The project was contracted out within budget and executed without constructional extra work.

After completing the design of the entire structure, Pieters has made all shape, reinforcement drawings and bending plates. The Belgian contractor Jan de Nul has executed the project within the planning and budget.

Return to the news overview