The possibilities and challenges of wood

"Wood is sympathetic material, but you have to apply it where it makes sense"

Hubert Kuijpers, branch manager of Pieters Bouwtechniek in Amsterdam, was named Constructor of the year 2018 last year due to his expertise in the field of wood structures. What are the possibilities and challenges of this sustainable building material?

Strong, durable and soothing

Where does Hubert’s interest in wood come from? “When I was a kid, we liked to build wooden huts. We always hoped that it would rain, to find out if we would keep it dry inside, "says Hubert. He went on to study Civil Engineering at TU Delft and decided during a study trip to Scandinavia to do his graduation research on wooden structures up to twelve floors. At the time, that was a fairly obscure subject, Hubert recalls. “Nobody wanted a house or building made of wood, among other things because of the maintenance, fire hazard and the risk of mold and bacteria damage. While wood is a very pleasant building material with a huge capacity. It is a relatively light material, just as strong as steel (mass-to-strength ratio), durable, easily available, pleasant to work on, insulates well and is also fully recyclable. There is also a great psychological aspect to the use of wood: it gives people a good feeling. I also notice that I almost immediately calm down when I am in a room where I am surrounded by wood, "says Hubert.

Challenges

As early as 1998, Hubert's graduation research showed that there are enough challenges for fully-timbered high-rise buildings. “Wood is orthotopic material: it is twenty times weaker in the transverse direction than in the longitudinal direction. The consequence of this is that you can hardly make any moment-proof connections, because the wood will then split. It is also a fairly weak material, so it often bends considerably. It is therefore difficult to get to the top without filling the building with wooden walls and diagonals for extra stability, "says Hubert. And then we are not even talking about issues in the field of noise and fire safety. So it's not surprising that concrete is usually chosen. This means that all issues are solved in one go, while when using wood you have to come up with a separate solution for each challenge. That makes building with wood not only complicated, but also expensive. According to Hubert, there are solutions, but that means that you have to do some pioneering work. “Architects who make a design for a wooden building really want to be able to see the material when they are in the building. They do not want to hide the wood behind a layer of plaster. From a cost-technical point of view, this desire often does not coincide with the standards that apply in the Dutch construction world. In short: there are still many questions to which I do not yet know the answer. But that is what makes it so interesting, "says Hubert. “I want to keep people on the ground with both feet. They must realize that there are still no standard solutions in many respects. As an implementing party you have to invest a lot of tuition in the process, because it has often not been done before. And because a contractor often has to deal with small margins, he is more likely to opt for a concrete structure, "says Hubert.

Good examples

rise buildings in a combination of wood and concrete. After all, the building must have enough mass to facilitate the certainty of the stand when the wind is strong. Examples are Patch22 and Top-Up, two sustainable, energy-neutral and circular construction projects in the Buiksloterham. Also at Hotel Jakarta on the Java island, one of the first energy-neutral hotels in the Netherlands, a combination is made of wood and concrete. The semi-basement cellar, the plinth and the floors of this high-rise are made of concrete, while wood is used as much as possible for the rest. “This was done not only to give the building more robustness and stability, but also to prevent moisture problems.

Take a wooden house in Canada as an example: you always see a concrete foundation below ground level that is used as a garage or basement. Very practical, with a view to possible flooding, "explains Hubert. This practical approach has also been used at Hotel Jakarta. “The load-bearing wooden walls on each floor protrude five centimeters above the floor. Inspired by the granito floors that you see a lot in 1930s houses, the concrete floor curls up five centimeters in each room before the wooden walls begin. For example, each room has become a small "bathtub", which means that the wood is at least safe if a bath floods or a sprinkler breaks. "Furthermore, unit construction has been chosen, which automatically creates double cavity walls that are effective against noise pollution. The installation of a sprinkler in every room ensures fire safety.

Compromise

As Hubert discovered in his graduation research in 1998, it is therefore possible to go up in height with wood. You just don't want to go too high. “A twelve-storey building can be done well without taking all kinds of measures for extra stability and sturdiness. For everything above that you must be prepared to compromise, as was done with the construction of Hotel Jakarta, Patch 22 and Top-Up. “Making everything from wood is difficult to achieve, because the stability and dynamics of the supporting structure is limiting. My plea is therefore not to break into pure wood concepts, but to use wood where it makes sense. ”

Patch22 | Image: Luuk Kramer

Patch22 | Image: Luuk Kramer

Patch22 | Image: Luuk Kramer

Patch22 | Image: Luuk Kramer

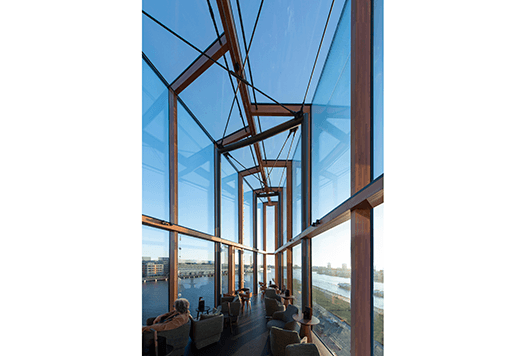

Hotel Jakarta | Image: SeARCH

Hotel Jakarta | Image: SeARCH

Hotel Jakarta | Image: SeARCH

Hotel Jakarta | Image: SeARCH

Hotel Jakarta | Image: SeARCH

Hotel Jakarta | Image: SeARCH

Return to the news overview