World first: 3D concrete printer gives flat a new face

Press release Bruil

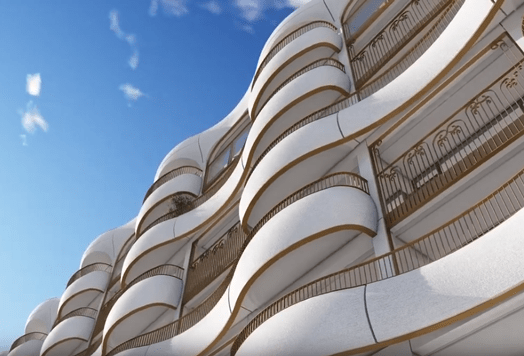

3D concrete printing in construction. You read more and more about it in the media. So far this revolutionary technology has only been used on a very limited scale. This will change early next year. In Den Helder, no fewer than 154 apartment houses - the first in the world - are fully upgraded with 3D-printed concrete elements. Almost 1,200 printed elements, ranging from 2 to 12 square meters, transform two buildings of gray and dull concrete into a unique and modern whole.

Facades and railings from the printer

In December this year, Bruil Prefab Printing will open an innovative factory in Veenendaal. A new flexible robot will print complete concrete façade elements, railings, and columns in this factory. Not straightforward, but with sloping, round shapes. Bruil, Kokon Architectuur & Stedenbouw and Helder Vastgoed together realize this unique project. The largest project worldwide in the area of 3D concrete printing! The two dated apartment buildings of seven floors each, built at the beginning of the 1970s, thus get a modern, Mediterranean look. Moreover, there will be more spacious balconies, a big wish of many residents.

Prefab Printing

Bruil has worked for around four years on the development of this technology and the construction of the factory. The enormous print robot can move through the hall via a rail system. "We are now able to produce unique building components every day. This project is a great opportunity to apply 3D concrete printing on a large scale for the first time, "explains Market and innovation manager Theo Voogd van Bruil. For the project in Den Helder, the printer will soon produce at least 30 façade elements. More than enough to be able to follow the work pace on the construction. "It is not only an innovative but also a sustainable solution. After all, you no longer need molds and hardly waste any concrete. "

Upgrading or new construction

Real estate manager Ton op 't Ende van Helder Vastgoed about the choice of 3D concrete print: "At a good moment we were faced with the question of what we would do with the flats. Leave it for another ten years and then push it flat or 'upgrade' it on the outside in such a way that the flats can last for forty years? We opted for the latter. That is much more sustainable than new construction. In addition, the solution that Bruil offers in this regard proved to be more affordable and much faster in terms of production time.

Invest in Den Helder

Housing association Den Helder will invest nearly 140 million euros in the coming four years in maintenance, renovation and sustainability of its existing home ownership. Via its development arm Helder Vastgoed BV, a multiple of that amount is also invested in urban renewal. For the improvement of these 2 apartment buildings, a special, controversial design by Kokon Architectuur and Stedenbouw from Rotterdam has been chosen, "We were inspired by the most beautiful architecture there is. Such as by Gaudí, the striking designer of, among others, the Sagrada Familia cathedral in Barcelona, "says Ron van Leeuwen (urban development architect / partner) of Kokon. "That means many round, organic forms. The elements that we envisaged cannot normally be produced or are priceless. With the Bruil 3D concrete printer we have been given much more freedom of form as an architect. That makes very special designs possible. "

Construction team

Over the past two years, a construction team of 8 companies has been involved in the design of Kokon. For example, the Movares and Pieters Bouwtechniek constructors are responsible for anchoring the printed elements and the main support structure respectively. Renovum supplies the steel decorative fencing. In addition, Bruil supplies prefab and Hi-con prefab elements and ultra high-strength balconies, and Ingenieursbedrijf Rijnders & de Groot is the main constructor. This month contractors can register for the construction of this project.

© 2019 Kokon Architectuur & Stedenbouw

© 2019 Kokon Architectuur & Stedenbouw

Return to the news overview